Our Services

Air Conditioning & Ventilation System

For regulation of indoor temperature, humidity, and air circulation, providing a comfortable and healthy environment. It ensures fresh air flow while filtering out pollutants, ideal for both residential and commercial spaces

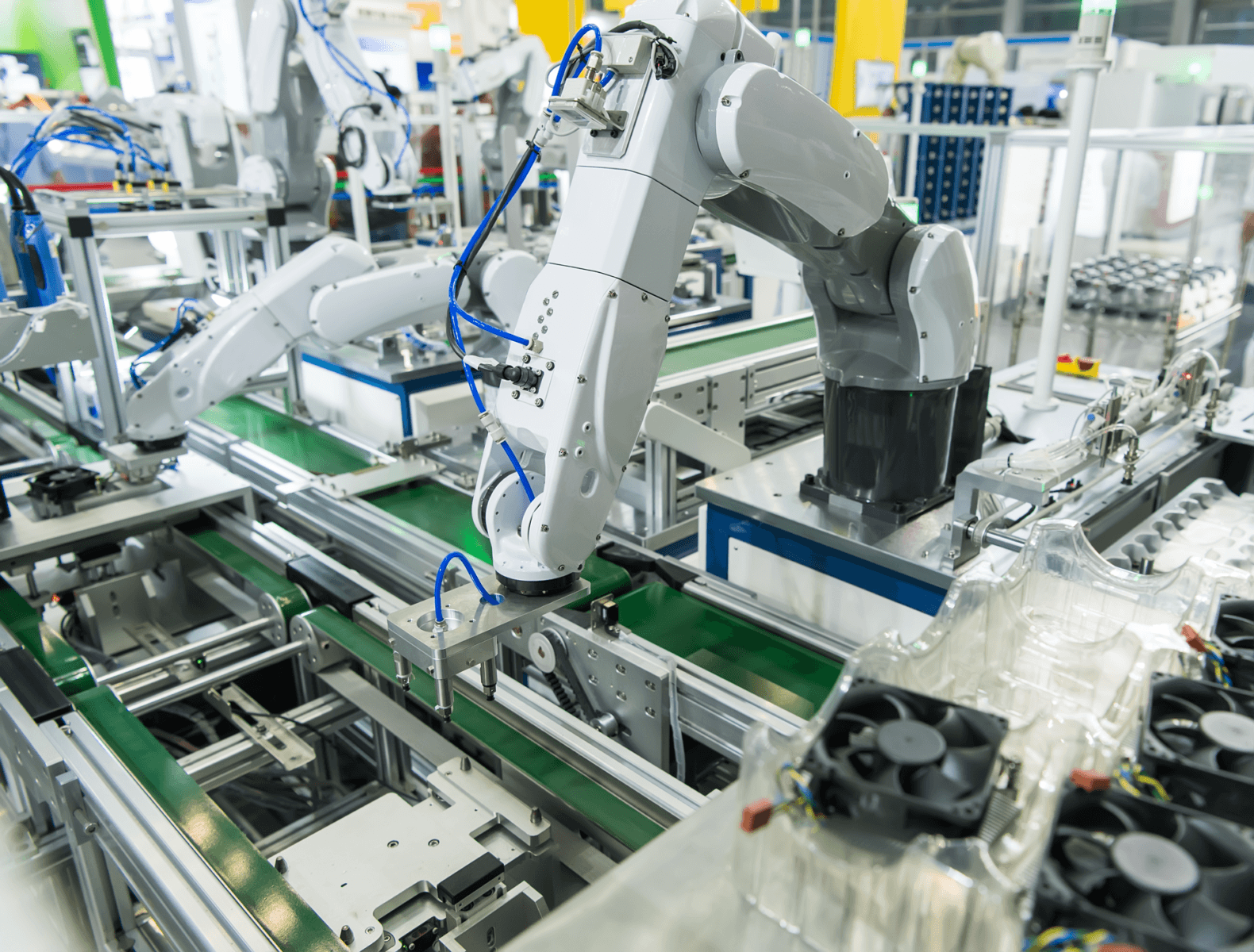

Mechanical System Works

Mechanical System Works involve the installation, maintenance, and repair of essential building systems, including HVAC, plumbing, and fire protection.

Process Cooling & Piping System

Process Cooling & Piping System is designed to remove excess heat from industrial processes and machinery, ensuring optimal performance and preventing overheating.

Refrigeration System

To removes heat from a space or substance to maintain low temperatures. It uses refrigerants in a cycle of compression and evaporation, ideal for cooling, preserving goods, and supporting various industrial processes.

Industrial Cleanroom

An Industrial Cleanroom is a controlled environment designed to maintain extremely low levels of airborne particles, dust, and contaminants.

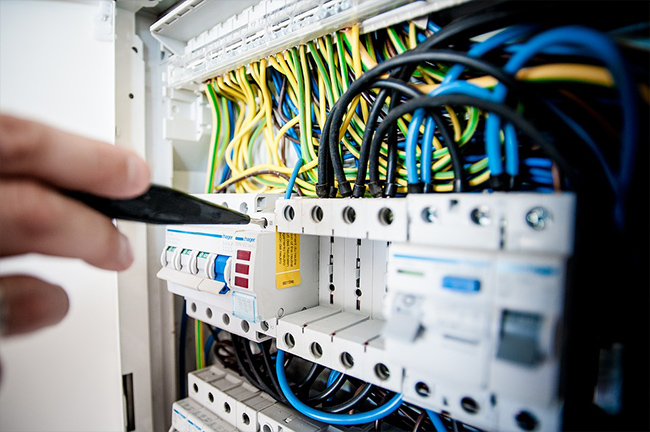

Electrical System & Civil Works

Electrical System & Civil Works encompass the design, installation, and maintenance of electrical infrastructure and supporting structures.

Air Conditioning & Ventilation System

Supply, Design, Installation, Maintenance, & Repair

Supply

Selection: Choosing suitable AC and ventilation equipment based on the building’s size and needs.

Procurement: Acquiring necessary components like AC units, ventilation fans, ductwork, and controls from suppliers.

Design

System Layout: Planning where AC units, ducts, and ventilation fans will be located to ensure efficient airflow and cooling.

Sizing: Determining the right capacity of AC units and ventilation fans to adequately cool and ventilate the building.

Installation

Assembly: Putting together AC units, ductwork, and ventilation fans according to the design plan.

Placement: Installing components in the correct locations to optimize airflow and cooling efficiency

Maintenance

Regular Checks: Periodically inspecting AC units, ventilation fans, and ducts to ensure they are working properly.

Cleaning: Removing dirt and debris from filters and components to maintain air quality and efficiency.

Adjustments: Making necessary adjustments to settings or components to optimize performance.

Repair

Diagnosis: Identifying issues with AC units, ventilation fans, or ductwork through troubleshooting and testing.

Fixing: Repairing or replacing faulty components to restore proper functioning.

Testing: Verifying that repairs have resolved the issue and ensuring the system operates

correctly.

Process Cooling & Piping System

Process Cooling:

• Purpose: Keeps machines and processes cool so they work well.

• How it Works: Uses chillers or cooling towers to lower temperatures.

• Design: Plans where chillers, pumps, and pipes go for best cooling.

• Installation: Puts in chillers, pumps, and pipes as planned.

• Maintenance: Checks and cleans everything regularly to prevent problems.

• Repair: Fixes any leaks or issues to keep cooling working right.

Piping System:

Purpose: Moves liquids or gases around a building or process.

• Design: Plans where pipes and valves go for good flow.

• Installation: Puts in pipes, fittings, and valves as planned.

• Maintenance: Checks for leaks or problems to keep pipes working.

• Repair: Fixes any leaks or replaces damaged parts to keep things flowing well.

Mechanical System Works

Purpose

Makes sure heating, cooling, and other systems in buildings work well.

What is involved?

Includes setting up, fixing, and maintaining HVAC, plumbing, and fire protection systems.

Tasks

Installation: Putting in HVAC units, pipes, and other equipment as needed.

Maintenance: Checking and cleaning systems regularly to keep them working.

Repairs: Fixing problems like leaks or broken parts.

Upgrades: Updating systems for better efficiency.

Testing: Checking that everything works right before using it.

Industrial Cleanroom

Food Processing:

• Purpose: Preventing contamination to ensure food safety.

• Design: Smooth surfaces for easy cleaning, strict air filtration to reduce particles.

• Cleaning: Regular and thorough sanitization of surfaces and equipment.

• Access Control: Restricted entry, with staff wearing protective gear.

• Monitoring: Continuous checks to maintain cleanliness standards.

• Regulations: Follow strict guidelines set by food safety authorities.

• Integration: Part of the food processing setup to maintain hygiene throughout production.

• Emergency Plans: Protocols for handling spills and other risks.

• Training: Ongoing education for staff on hygiene practices.

Pharmaceutical:

• Purpose: Keeps medicines safe from particles and germs.

• Design: Smooth surfaces for easy cleaning, special air filters for purity.

• Cleaning: Strict cleaning with sterile solutions to maintain cleanliness.

• Access Control: Only authorized staff in special clothing to limit contaminants.

• Monitoring: Constant checks to ensure cleanliness meets standards.

• Regulations: Follows strict rules from health authorities.

• Integration: Part of the medicine-making process to ensure quality.

• Training: Staff trained in cleanroom procedures for safety.

Semiconductor:

• Purpose: Keeps the air extremely clean to ensure top-quality chip production.

• Design: Smooth materials and special air filters to remove tiny particles.

• Cleaning: Strict cleaning to keep everything spotless.

• Access: Only authorized people in clean suits can enter to avoid dirt.

• Monitoring: Always checking air and cleanliness levels.

• Rules: Follows strict rules to make sure chips are perfect.

• Integration: Part of making chips to control quality.

• Training: Staff trained to keep clean and follow rules.

Our Services Include:

• Cleaning: Regular and thorough cleaning using approved methods and disinfectants.

• Validation: Tests to ensure cleanrooms meet cleanliness standards.

• Monitoring: Continuous checks on temperature, humidity, and particle levels.

• Supplies: Providing equipment and supplies needed for cleanliness.

• Training: Teaching staff how to maintain cleanroom standards.

• Compliance: Ensuring cleanrooms meet industry regulations.

Refrigeration System

Supply

Selection: Choosing the right refrigeration equipment (like fridges or freezers) based on cooling needs.

Getting Equipment: Getting units and parts from suppliers.

Design

Planning: Figuring out where to put units for best cooling.

Choosing Size: Picking the right size for how much needs to be cooled.

Installation

Setting Up: Putting in units and connecting pipes as planned.

Testing: Checking everything works as it should.

Maintenance

Regular Checks: Looking over equipment to find and fix problems early.

Cleaning: Keeping coils and filters clean for better cooling.

Repair

Finding Issues: Figuring out what’s wrong with units.

Fixing: Repairing or changing parts to make sure everything cools properly.

Electrical System

Supply:

• Purpose: Gets all the wires, switches, and other parts needed.

Design:

• Purpose: Plans where everything goes.

• Process: Decides where outlets, switches, and wires will be.

Installation:

• Purpose: Puts everything in place.

• Process: Puts wires in walls, installs outlets, switches, and panels.

Maintenance:

• Purpose: Checks everything works okay.

• Process: Inspects wires and tests switches and outlets. Cleans and fixes anything broken.

Repair:

• Purpose: Fixes any problems.

• Process: Finds and repairs broken wires, switches, or outlets.

Stainless Steel Fabrication

Purpose

Shapes stainless steel into usable parts or structures.

Process

Cutting: Cuts stainless steel into pieces.

Forming: Bends or shapes it into needed forms.

Welding: Joins pieces together.

Finishing: Adds textures or shines.

Use

Construction: Makes building parts.

Manufacturing: Creates machinery parts.

Custom Projects: Builds unique items.

Benefits

Strong and resistant to rust, good for many industries.

Civil Works

Ceiling:

• Purpose: Covers the top inside of a room.

• Materials: Uses drywall, tiles, or panels.

• Installation: Puts up materials to hide wires and pipes.

Cement:

• Purpose: Binds materials together in construction.

• Use: Pours foundations and makes walls and floors.

Brick Wall:

• Purpose: Makes strong walls.

• Materials: Uses fired clay bricks or concrete blocks.

• Construction: Stacks bricks or blocks with mortar.

Partition:

• Purpose: Divides rooms or spaces.

• Materials: Made of drywall, glass, wood, or metal.

• Installation: Builds walls or panels to make separate areas.

Glass:

• Purpose: Lets light through.

• Types: Clear, tinted, tempered, or laminated.

• Use: Puts in windows, doors, and walls.

Other Elements:

• Flooring: Puts down tiles, wood, or concrete for walking.

• Doors and Windows: Adds entrances and light openings.

• Finishes: Decorates with paint or wallpaper.

At Ashrae, we are committed to delivering exceptional solutions that meet your needs for comfort, safety, and sustainability. Whether you require innovative HVAC systems, process cooling, or comprehensive mechanical and electrical services, our team of experts is here to provide reliable, efficient, and tailored services. Contact us today to learn how we can help drive your project to success!